- Products

- Plastics, composites, recyclates, compounds

- Specimen preparation

- CNC Specimen Milling and Notch Cutter

CNC Specimen Milling and Notch Cutter

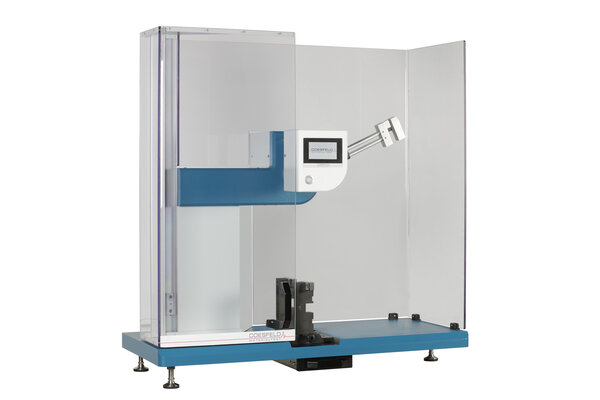

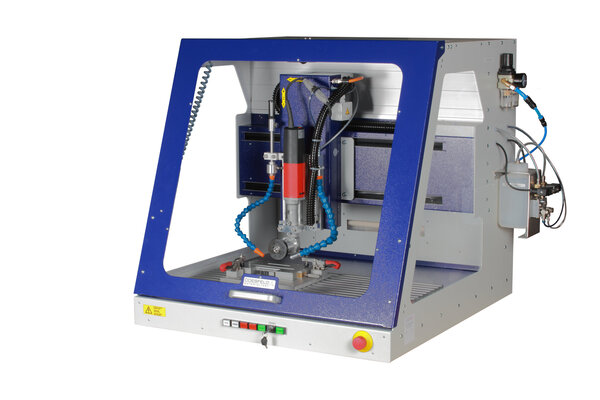

Fully automated three-axis-machine for test specimen production and processing-bearbeitung

Properties

- Cutting and notching possible

- Rich library of milling files for standard specimen (DIN / EN / ISO / ASTM)

- Creation of individual milling files possible

- Selection of single and multiple clamping devices (customized production possible))

- Suitable for plastics (e.g. PE/PA/PC/PMMA/GFK and CFK compounds), aluminium, brass and wood (other materials on request)

- CE-conform safety housing

Traverse path X/Y/Z

400 x 300 x 140 mm

Axis speed X/Y/Z

up to 20 mm/s

Pass-through height

170 mm

T-nut clamping plate W x D

600 x 375 mm

Sound pressure level

< 75 dB(A)

Dimensions W x D x H

750 x 850 x 810 mm

Weight

120 kg

Mains

230 V, 50 Hz, 1500 W

ASTM D256

DIN 53435

DIN EN ISO 179-1

DIN EN ISO 180

DIN EN ISO 75

DIN EN ISO 8256

DIN EN ISO 527-2 Typ 1A

DIN EN ISO 527-2 Typ 1B

DIN EN ISO 527-2 Typ 1BA

DIN EN ISO 527-2 Typ 1BB

DIN EN ISO 527-2 Typ 5A

DIN EN ISO 527-2 Typ 5B

DIN EN ISO 527-2 Typ 2

DIN EN ISO 527-2 Typ 4

DIN EN ISO 1798 Typ 1

ASTM D638

DIN 53453

DIN 53455

DIN 53504

DIN 53571

ISO 6259

ASTM D790

ASTM E96

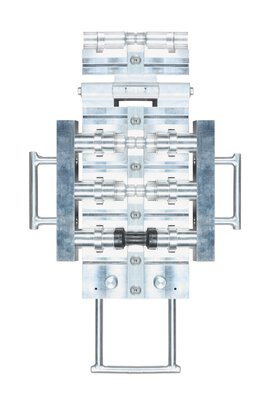

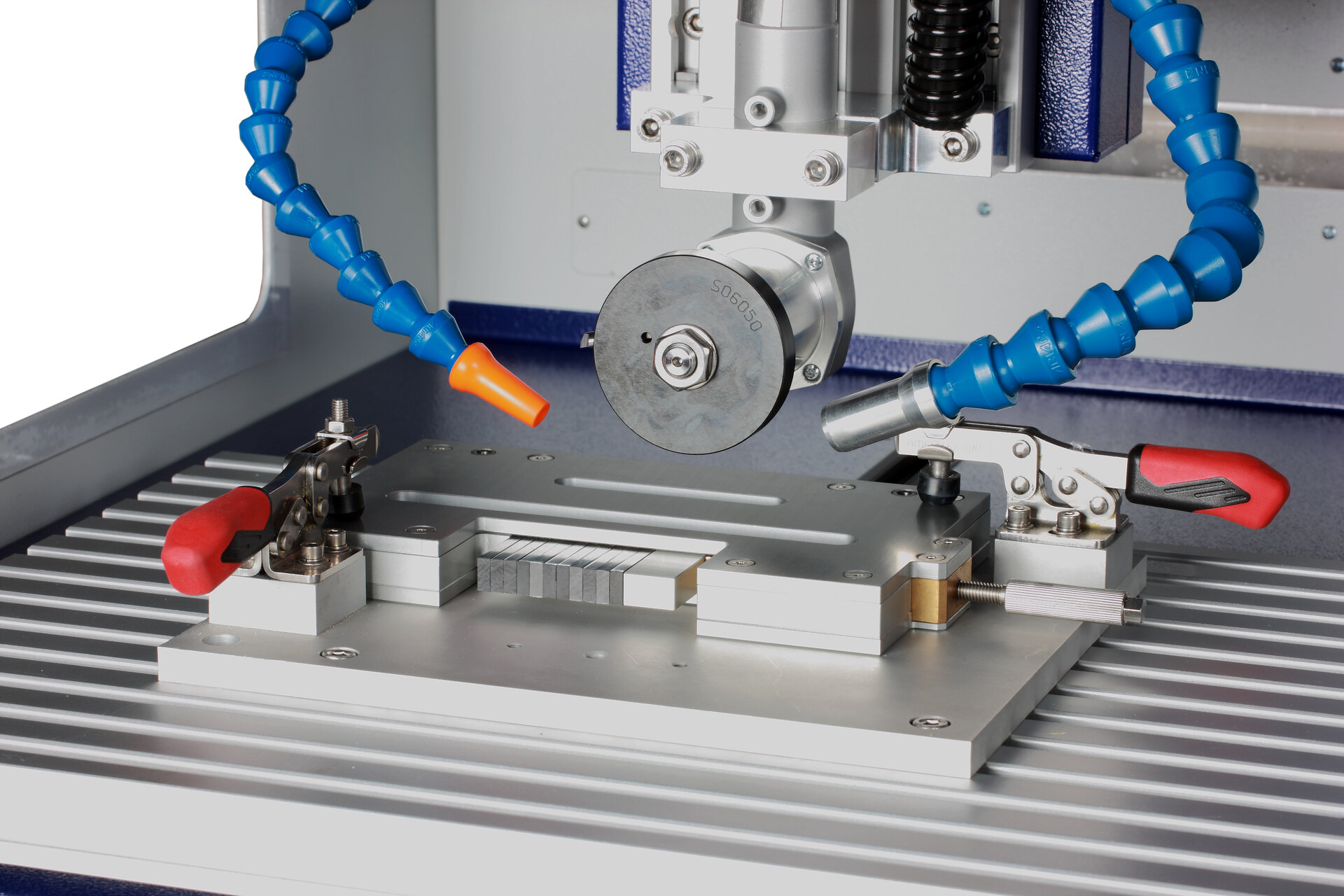

Form-locking multiple clamping device for standard bars

Set-up with base plate for DIN EN ISO 527 standard bards. Universal multiple clamping devices or form-locking multiple clamping devices of particular specimen bars are available. The assembly shows cooling via cold air nozzle per pressurized air.

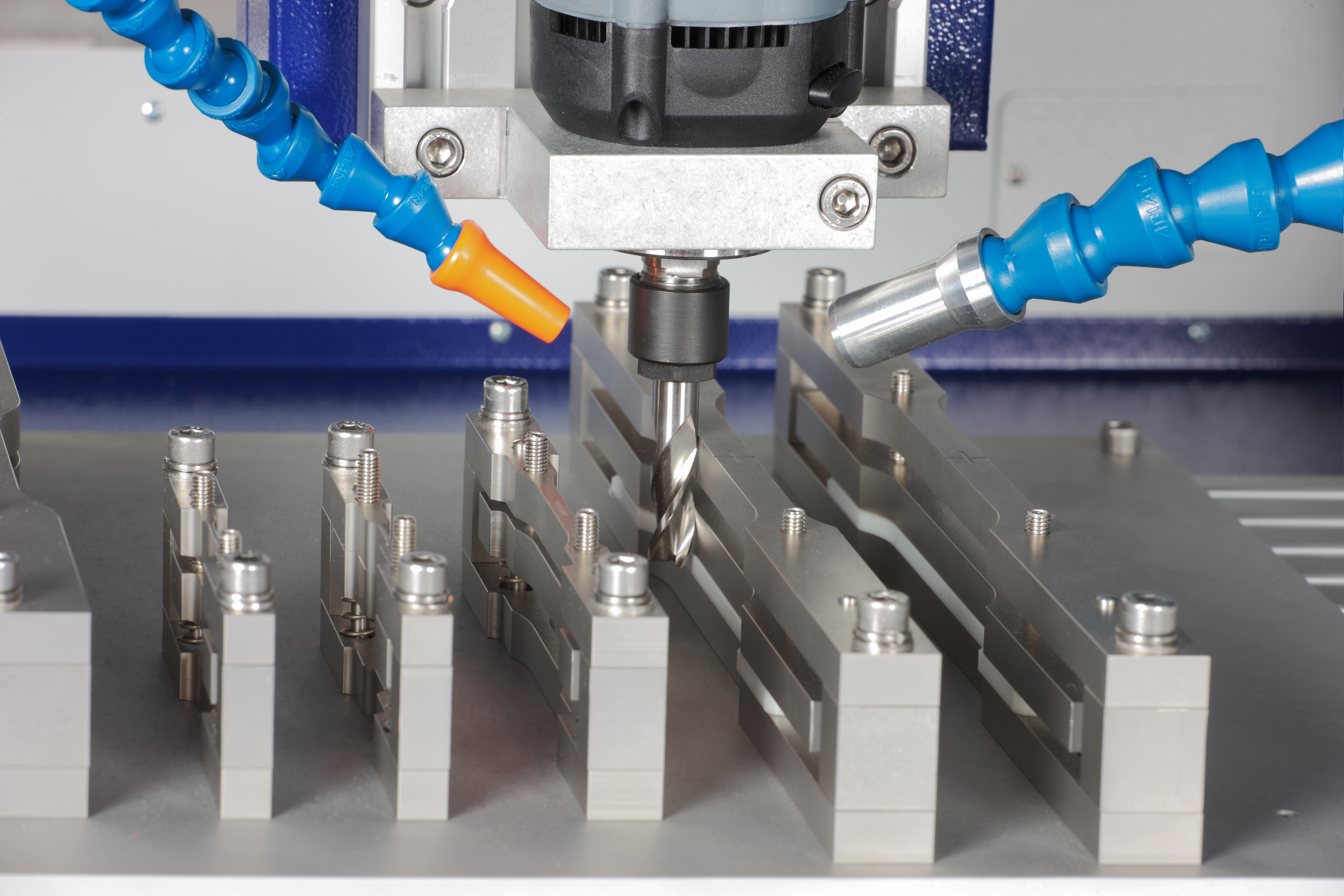

Notching assembly with revolving magazine

Standard conform single and double notching up to 30 specimen bars acc. to ISO 179, ISO 180, ASTM D6110, ASTM D256, ASTM D4812. Upgrade to simultaneous cutting of the specimen shoulders is possible. Multiple use of milling and notching machine is feasible.

More products

PIT 25/50 - Pendulum Impact Tester

Impact pendulum for Charpy, Izod and impact tensile tests up to 25/ 50 Joule

Vulcanisation sample molds

Steel molds for vulcanization of elastomer specimen. Steel molds for vulcanization of elastomer. Precise milling contours and set pins for exact and easy positioning. Large handles and screw inserts for simple separation of the plates after molding.