- Products

- Plastics, composites, recyclates, compounds

- Impact resistance

- IIT 2000 - Instrumented Impact Tester

IIT 2000 - Instrumented Impact Tester

Puncture and impact resistance measurement up to 2000 Joule

Properties

- Multipurpose due to modular machine design

- Intuitive software with automatic data evaluation

- Quick Test Execution in < 5 Seconds

- High Test Energies up to 2000 Joule

- Lossless scalable force measurement

Description

The IIT 2000 is an Instrumented Impact Tester with drop weight, impact velocity, and high dynamic impact force profile measurement. Optional optical measurement of the puncture distance or rebound height is also possible.

The Impact Tester is designed for multi-axial impact testing according to DIN EN ISO 6603-2, DIN EN ISO 7765-2 and ASTM D 3763. Due to the modular machine concept, the device can be extended by acceleration units for puncture testing for the automotive industry, such as GMW 14867. The test setup can also be equipped for various high-speed tests, such as the impact tensile test DIN EN ISO 8256, ASTM D1822, the peel-wedge test according to ISO 11343 or following the classical pendulum impact tests such as Charpy DIN EN ISO 179, ASTM D6110, Izod DIN EN ISO 180, ASTM D256, ASTM D4508 up to part and component tests.

Additional equipment such as automatic specimen fixation, dart lubrication, anti-rebound catch system, variable drop weights, impactor geometries and test setups are available to match international standards or we can design and manufacture the setup to your individual requirements.

Drop Height

up to 1300 mm

Impact Engery

up to 2000 J

Impact Speed

up to 20 m/s

Drop Weight

up to 80 kg

Tempering Chamber

-70 to +150 °C

Dimensions (W x D x H)

approx. 1000 x 1000 x 2600 mm

Weight

approx. 750 kg

Compressed Air Supply

5-10 bar

Mains

230 V, 50/60 Hz, 500 VA

ASTM D1822

ASTM D256

ASTM D4508

ASTM D6110

DIN 53373

DIN 65561

DIN EN 1411

DIN EN 6038

DIN EN 744

DIN EN ISO 11343

DIN EN ISO 180

DIN EN ISO 3127

DIN EN ISO 6603-2

DIN EN ISO 7765-2

DIN EN ISO 8256

DIN ISO 18352

GMW 14867

ASTM D3763

ASTM D7192

DIN ISO EN 179-2

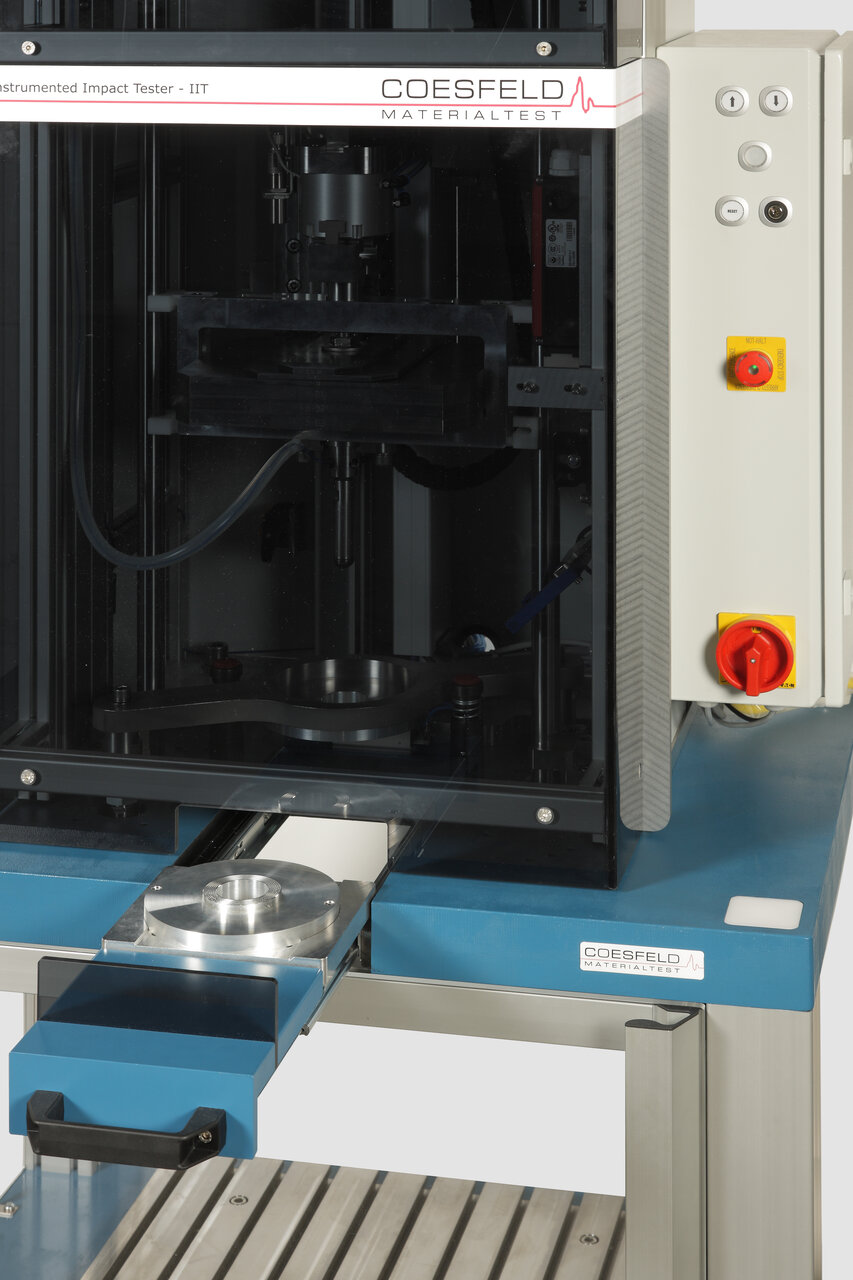

Practical specimen feed for classic puncture testing

For the classic multi-axial puncture test according to DIN EN ISO 6603-2, DIN EN ISO 7765-2 and ASTM D 3763, we offer a practical and ergonomic sample feed via a drawer. The sample can be supplied conveniently and quickly. In combination with a sample freezer provided, the samples can be quickly supplied and tested in less than 5 seconds. The user can check the entire measurement series directly in front of the device as a series and then view the results on the PC. For manual testing at low temperatures, a provided freezer is often easier to handle than a temperature control chamber surrounding the test room.

Integrated temperature chamber and automatic sample feed

The entire test room can be surrounded by a temperature control chamber. This makes particular sense for component and part testing or for automated sample feeding for the muti-axial standard puncture test. With automatic sample feed, the temperature control chamber is brought up to the test temperature once and an entire measurement series of up to 30 test specimens can be processed without opening and temperature loss.

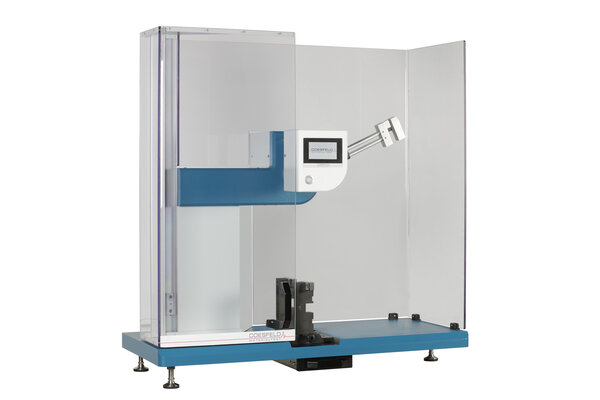

Compact test base for limited ceiling height

The test socket is a modular component and can be designed according to your individual needs. It is therefore possible to integrate a temperature chamber or to use a minimalist test base to reduce the overall system height with limited ceiling height. In this way, we can easily install the device even with standard ceiling heights. Accessibility and ergonomics are also taken into account here, despite the low test height, via a practical V-cut in the carrier plate.

Component Testing

For large components such as car bumpers or dashboards, which cannot be cut out in the device or should not be shredded for handling reasons, the test space can be enlarged to practically any size so that the component can be inserted completely. We look forward to your individual request.

More products

PIT 25/50 - Pendulum Impact Tester

Impact pendulum for Charpy, Izod and impact tensile tests up to 25/ 50 Joule