- Products

- Plastics, composites, recyclates, compounds

- VICAT/ HDT

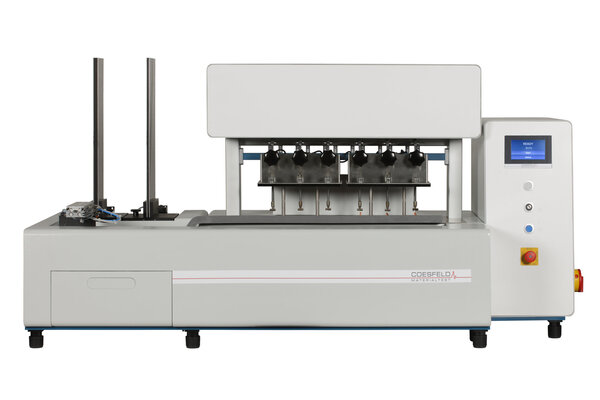

- NEW: HDT Automat 6

NEW: HDT Automat 6

Fully automated HDT tester with sample feeder

Properties

- Auto Weight Selection and Application

- Auto Sample Feeding

- Integrated Oil-Fume Exhaust

- Large Bath Opening for Service and Cleaning Acess

- Optional: Fast Cooling in < 15 min

Description

The HDT fully automatic machine not only has an automatic sample feeding system, but also a unique, step-free, automatic load application. The weight is automatically selected and applied according to the method and sample geometry. The device is used for standard-compliant measurement of the HDT (Heat Distortion Temperature) according to international standards in 24/7 continuous operation. It has 6 measuring stations that are operated in parallel with the same or different measuring jobs.

High-temperature-stable silicone oil is used as the heat transfer medium. An integrated, exhaust nsures that oil vapors are extracted in a controlled manner and optionally cleaned with a filter. The optimized oil bath achieves even better oil distribution and an even more precise heating gradient. The heating gradient is checked and documented with each measurement at the 6-minute interval required by the standard. By reducing the amount of oil at the same time, even faster cooling times can be achieved. The tried-and-tested high-performance cooling can also be optionally added for even faster cooling and higher device throughput.

Operation is optionally via the integrated touch panel or the associated Windows software. In addition to finished reports, a complete raw data export in csv format is available, as is typical for Coesfeld.

Temperature

20 to300 °C (optional up to 350°C)

Travel Resolution

0.001 mm

Bathvolume

11.5 Liter

Cooling Time (300 °C -> RT)

~40 min (optional <15 min)

Dimensions H x D x W

1.000 x 736 x 1.600 mm

Weight

150 kg

Mains

230 V, 50 Hz, 3200 W

ASTM D648

BSI 2782 Met 121 C

DIN 53461

DIN EN ISO 75

NT T 51-005

UNE 53075

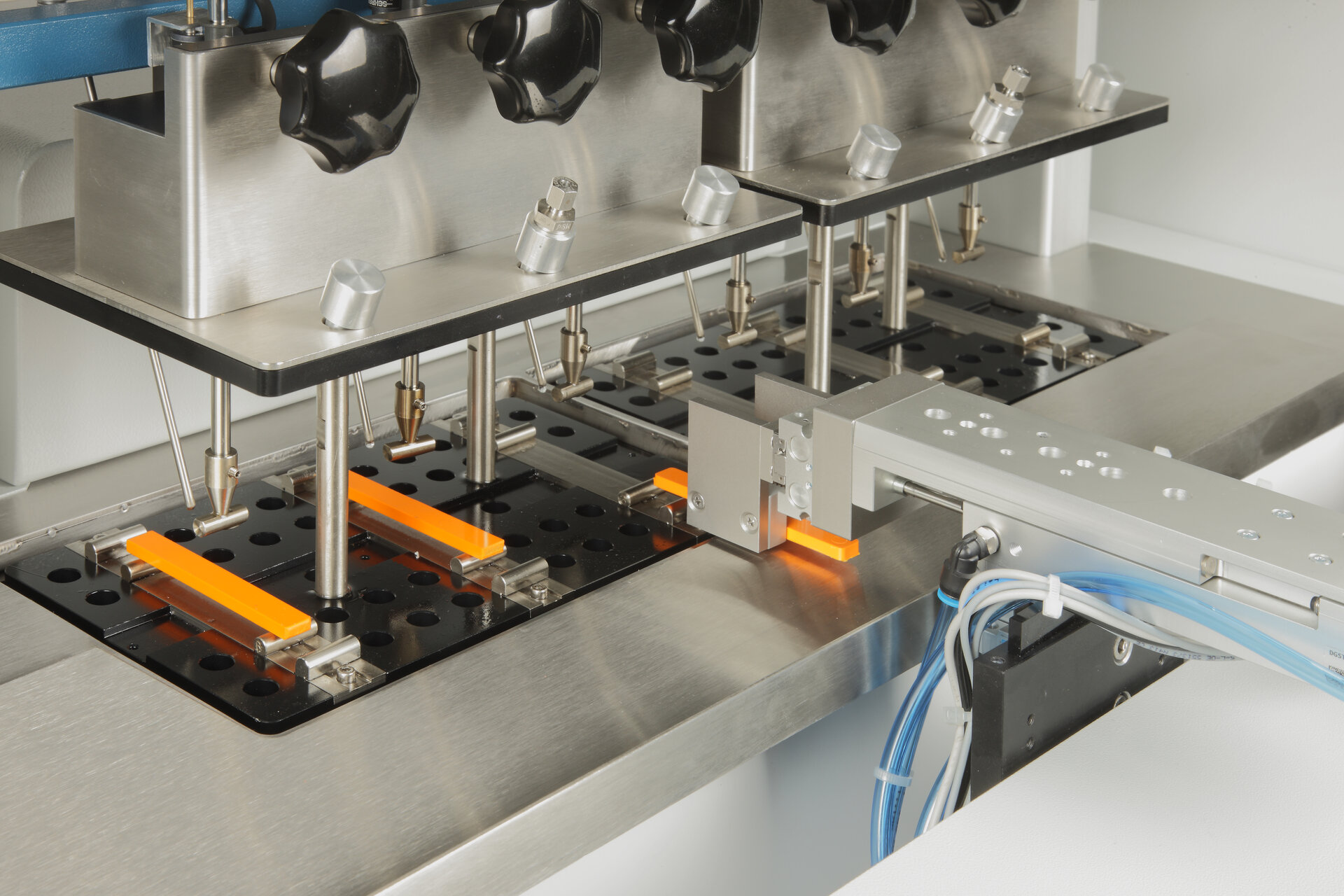

Sample Feeding (ISO / ASTM)

A two-finger gripper picks up the samples from the prepared magazines. Two magazine slots are available, which can be equipped for ISO and/or ASTM samples with a total of up to 120 samples (20 automatic measurement runs). During automatic operation, samples can be added and the test order list can be supplemented.

Sample Supports (ISO / ASTM)

The measuring stations are equipped with supports for ISO and ASTM, so that an automatic change between or mixing of ISO and ASTM orders is possible in the same measurement run.

Tested Samples

After each test run, the samples are thrown into the easily accessible drawer, ensuring easy and smudge-free disposal of the samples.

More products

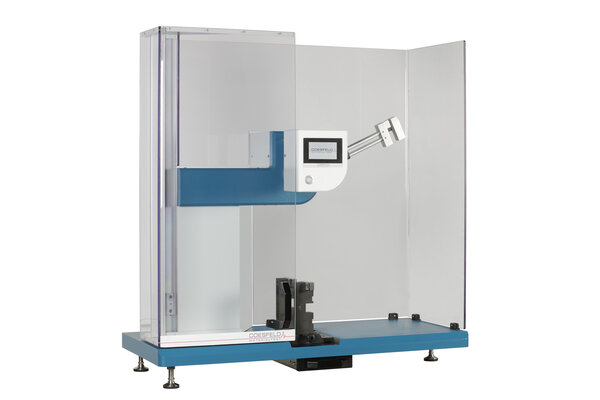

NEW: VST/ HDT Standard 6

Compact Tabe-Top Unit with 6 Stations for industrial HDT and VST measurement

ECO VST Automat (oilfree)

Sample feeding unit as an add on to standard ECO VST for full automation for 24/7 VST measurement

PIT 25/50 - Pendulum Impact Tester

Impact pendulum for Charpy, Izod and impact tensile tests up to 25/ 50 Joule