- Products

- Plastics, composites, recyclates, compounds

- VICAT/ HDT

- NEW: VST/ HDT Standard 6

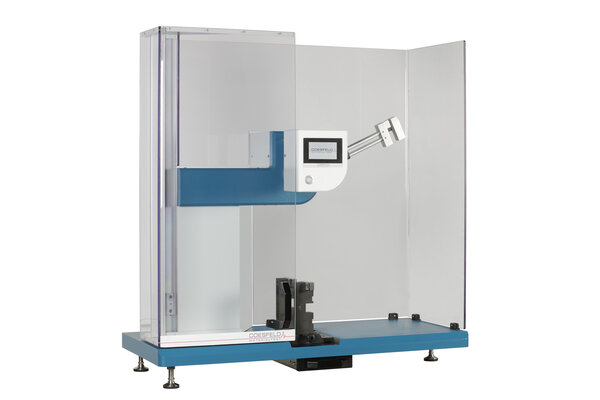

NEW: VST/ HDT Standard 6

Compact Tabe-Top Unit with 6 Stations for industrial HDT and VST measurement

Properties

- Automatic weight application via motorized lift

- Free and intuitive Win-Software (LIMS-Ready)

- Large bath opening for easy service and cleaning access

- Ready for composites acc. ISO 75-3

- Integrated oil-fume exhaust

Description

The standard VST/ HDT is partially automated with a motorized measuring head lifting platform and weight support. It is designed for industrial operation.

The device is used for standard-compliant measurement of VST (Vicat Softening Temperature) and HDT (Heat Distortion Temperature) according to international standards. It is available in two versions with 3 (Standard 3) or 6 (Standard 6) measuring stations. For the first time, it is possible to measure the HDT of composites according to ISO 75-3 using transverse supports.

High-temperature-stable silicone oil is used as the heat transfer medium. An integrated exhaust ensures that oil vapors are extracted in a controlled manner and optionally cleaned with a filter.

The optimized oil bath achieves even better oil distribution and an even more precise heating gradient. The heating gradient is checked and documented with each measurement at the 6-minute interval required by the standard. By reducing the amount of oil at the same time, even faster cooling times can be achieved. A high-performance cooling can also be optionally added for even faster cooling and higher device throughput.

Operation is optionally via the integrated touch panel or the associated Windows software. In addition to finished reports, a complete raw data export in csv format is available, as is typical for Coesfeld.

Temperature

20 to 300 °C (optional up to +350 °C)

Travel Resolution

0,001 mm

Bathvolume

11,5 l

Cooling Time (300 °C -> RT)

~ 40 min (optional <15 min)

Dimensions H x D x W

790 x 560 x 1040 mm

Weight

70 kg

Mains

230 V, 50 Hz, 3200 W

ASTM D1525

ASTM D648

BSI 2782 Met 120 C

BSI 2782 Met 121 C

DIN 53461

DIN EN ISO 306

DIN EN ISO 75

NT T 51-005

NT T 51-021

UNE 53118

DIN EN ISO NF 2507

DIN EN 727

Integrated Color Touch Panel

The measurement can be fully controlled via the integrated touch display. A PC is not absolutely necessary. At the same time, it is also possible to perform measurements and manage measurement data using the software included as standard with the device. The touch panel is then used for a clear device status display and simple "continue" commands can also be given via the operating button. Integration into your LIMS (Laboratory Information Management System) is also possible.

Measurment Head acc. to ISO and ASTM requirements – inclusive ISO 75-3

The devices are equipped with one or two 3 measuring heads so that 3 or 6 measuring stations are available. Each measuring station has its own displacement sensor and temperature sensor. It is easy to change from Vicat to HDT by exchanging the measuring tip. The fulfillment of ISO 75-3 for the composite measurement through transverse sample supports is unique.

More products

NEW: VST/ HDT Safety Housing

Optional Housing for VST/ HDT Basic 3 / Standard 6 / Standard 6

CNC Specimen Milling and Notch Cutter

Fully automated three-axis-machine for test specimen production and processing-bearbeitung

PIT 25/50 - Pendulum Impact Tester

Impact pendulum for Charpy, Izod and impact tensile tests up to 25/ 50 Joule